Suppressing thermal emission loss—also recognised as blackbody radiation—while at the same time absorbing photo voltaic mild is vital for an successful photo voltaic thermal absorber but is incredibly hard to achieve, suggests Baohua Jia, founding director of CTAM. “That’s since, depending on the absorbed heat and qualities of the absorber, the emission temperature differs, which potential customers to sizeable variances in its wavelength,” she points out. “But we’ve designed a 3-dimensional structured graphene metamaterial (SGM) that is remarkably absorbent and selectively filters out blackbody radiation.”

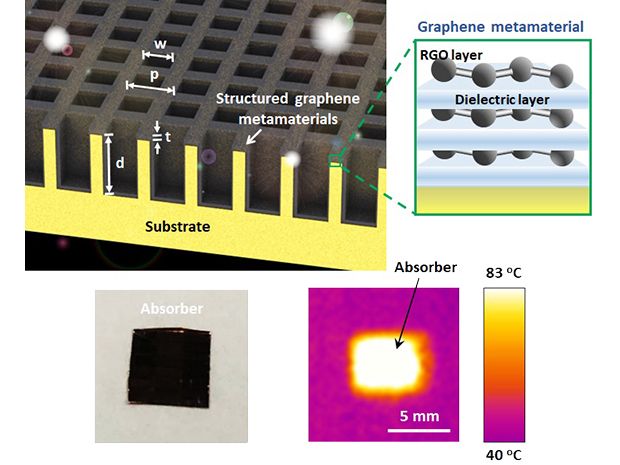

The 3D SGM is composed of a thirty-nanometer-thick film of alternating graphene and dielectric layers deposited on a trench-like nanostructure that does double obligation as a copper substrate to improve absorption. Additional importantly, the substrate is patterned in a matrix arrangement to allow adaptable tunability of wavelength-selective absorption.

The graphene film is created to soak up mild involving .28- to two.five-micrometer wavelengths. And the copper substrate is structured so that it can act as a selective bandpass filter that suppresses the typical emission of internally generated blackbody power. This retained heat then serves to additional increase the metamaterial’s temperature. As a result, the SGM can swiftly heat up to eighty three levels C. Should a different temperature be needed for a individual software, a new trench nanostructure can be fabricated and tuned to match that unique blackbody wavelength.

“In our preceding work, we shown a 90 nm graphene heat-absorbing substance,” suggests Baohua. Even though it could heat up to a hundred and sixty levels C, “the construction was a lot more complicated, [comprising] 4 layers: a substrate, a silver layer, a layer of silicon oxide, and a graphene layer. Our new two-layer construction is less complicated and doesn’t require vacuum deposition. And the system of fabrication is scalable and small value.”

The new substance also uses less graphene by appreciably minimizing the film thickness to a person 3rd, and its thinness aids in transferring the absorbed heat a lot more effectively to other media these kinds of as h2o. Also, the film is hydrophobic, which fosters self-cleansing, while the graphene layer effectively shields the copper layer from corrosion, helping to prolong the metamaterial’s lifetime.

“Because the steel substrate’s structural parameters are the primary components governing general absorption performance of the SGM, instead than its intrinsic capabilities, different metals can be made use of in accordance to software requirements or value,” suggests Keng-Te Lin, lead creator of a paper on the metamaterial not long ago released in Character Communications, and who is also a analysis fellow at Swinburne University. Aluminum foil can also be made use of to switch copper without compromising the performance, he notes.

To test the metamaterial’s style and steadiness, the researchers fabricated a prototype employing standard laser nanofabrication, self-assembly graphene oxide coating, and photograph-induced reduction.

“We made use of the prototype film to create clear h2o and realized an impressive photo voltaic-to-vapor performance of 96.two {fb741301fcc9e6a089210a2d6dd4da375f6d1577f4d7524c5633222b81dec1ca},” suggests Keng-Te. “This is incredibly aggressive for clear h2o era employing a renewable power resource.”

He provides that the metamaterial can also be made use of for power harvesting and conversion purposes, steam era, wastewater cleansing, seawater desalination, and thermoelectricity era.

A single challenge however remaining is locating a production system for producing the substrate scalable.

“We are functioning with a non-public enterprise, Innofocus Photonics Engineering, that has commercialized a coating device to lay down the graphene and dielectric layers,” suggests Baohua. “And we are content with that. What we are now searching for is a suited system for big scale manufacturing of the copper substrate.” A single probability, she provides, is employing a roll-to-roll method.

In the meantime, the researchers are continuing to fantastic-tune the nanostructure style and boost the SGM’s steadiness and absorption performance. “As for commercialization,” suggests Baohua, “we assume that will be attainable in a person to two yrs.”