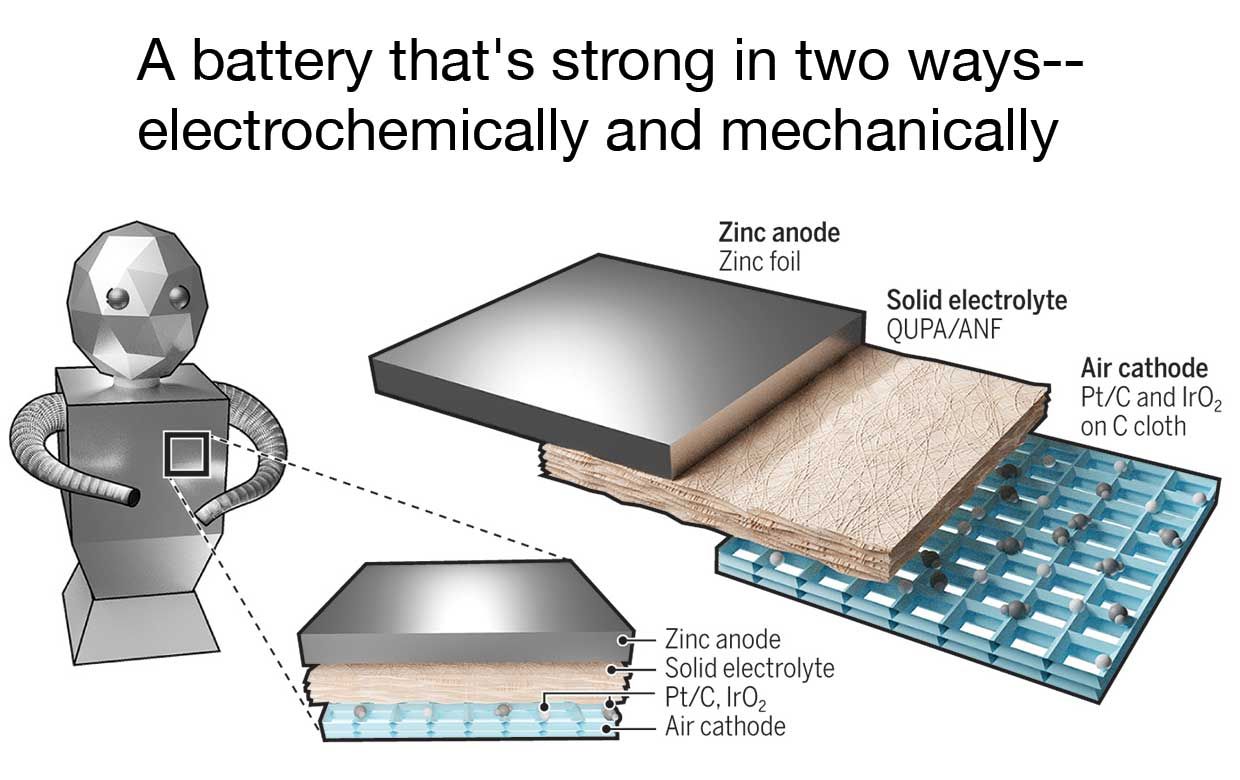

Batteries can include sizeable mass to any layout, and they have to be supported using a adequately strong structure, which can include sizeable mass of its have. Now researchers at the University of Michigan have made a structural zinc-air battery, a single that integrates right into the machine that it powers and serves as a load-bearing portion.

That feature will save pounds and therefore improves effective storage capacity, adding to the already hefty electrical power density of the zinc-air chemistry. And the pretty elements that make the battery physically strong assist have the chemistry’s longstanding tendency to degrade in excess of quite a few hundreds of charge-discharge cycles.

The exploration is being published right now in Science Robotics.

Nicholas Kotov, a professor of chemical engineer, is the leader of the undertaking. He would not say how quite a few watt-hours his prototype shops per gram, but he did note that zinc air—because it draw on ambient air for its electric power-creating reactions—is inherently about three times as electrical power-dense as lithium-ion cells. And, mainly because using the battery as a structural part means dispensing with an interior battery pack, you could absolutely free up maybe twenty per cent of a machine’s interior. Along with other elements the new battery could in principle deliver as a great deal as seventy two times the electrical power per device of volume (not of mass) as today’s lithium-ion workhorses.

“It’s not as if we invented anything that was there just before us,” Kotov claims. ”I look in the mirror and I see my layer of fat—that’s for the storage of electrical power, but it also serves other purposes,” like trying to keep you warm in the wintertime. (A related advance happened in rocketry when designers learned how to make some liquid propellant tanks load bearing, removing the mass penalty of having individual external hull and interior tank walls.)

Many others have spoken of placing batteries, such as the lithium-ion kind, into load-bearing sections in autos. Ford, BMW, and Airbus, for occasion, have expressed interest in the strategy. The major difficulty to overcome is the tradeoff in load-bearing batteries between electrochemical effectiveness and mechanical power.

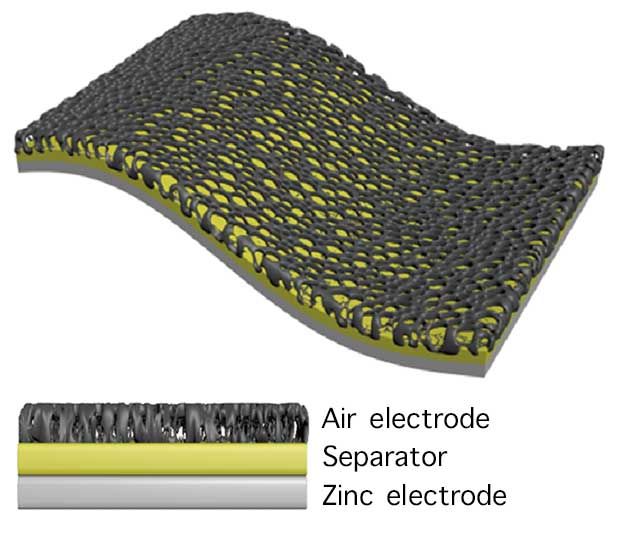

The Michigan group get each attributes by using a stable electrolyte (which can not leak less than strain) and by masking the electrodes with a membrane whose nanostructure of fibers is derived from Kevlar. That will make the membrane hard plenty of to suppress the development of dendrites—branching fibers of metal that tend to sort on an electrode with each individual charge-discharge cycle and which degrade the battery.

The Kevlar need not be acquired new but can be salvaged from discarded overall body armor. Other production methods must be uncomplicated, far too, Kotov claims. He has only just begun to chat to opportunity professional companions, but he claims there’s no reason why his battery couldn’t hit the current market in the following three or four decades.

Drones and other autonomous robots may be the most logical to start with software mainly because their vary is so severely chained to their battery capacity. Also, mainly because such robots never carry men and women about, they facial area fewer of a hurdle from security regulators leery of a fundamentally new battery style.

“And it is not just about the massive Amazon robots but also pretty smaller kinds,” Kotov claims. “Energy storage is a pretty sizeable situation for smaller and flexible smooth robots.”

Here’s a movie exhibiting how Kotov’s lab has utilized batteries to sort the “exoskeleton” of robots that scuttle like worms or scorpions.